Great Information on Link Weldments for YOUR BHS!

Categories: Industry News

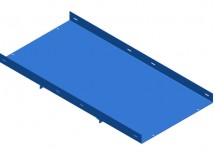

Tara: Hello there. I’m Tara Riggs and this is Colin Sanburg and we’re here with Unified Supply. So today we’re going to talk about a link weldment. That’s what we call this particular part that goes in the carousel. And Colin’s going to give us a little overview of the different types of names that we hear in the industry that is used for a link weldment, and also what it’s used for on the carousel. So…

Colin: Sure. So, the most common name and what we’ve kind of standardized because we help customers with a lot of different product lines, so for our own sanity’s sake we’ve tried to streamline our conversation. We call all of these link weldments. However, some of the different designs that have been made over the years have referred to them as carrier weldments, carrier links, link assemblies, flights. They’ve been named all different types of things. But, the basic idea is on a flat-plate carousel, you’ve got…this is the support mechanism underneath your crescent pallet.

Tara: Great, and so, tell me exactly what it’s used for on the carousel, what it connects to, and how it helps the function of the carousel.

Colin: Sure. So like I said, it’s the support mechanism under your crescent pallet, and there’s all different types of styles. Some of them have a big crossbar that you would see here that may have support rollers in them, and those support rollers run on top of the frame. Other ones, like this style, this is for a stern, and this particular style on the TransiTread is obviously a little bit smaller than that. It’s more streamlined.

The crescent pallet itself rests on top of support rollers which are mounted in the frame. So it’s just a different way of accomplishing the same thing, but this being the basic support mechanism that goes around, it’s the pivot point so we’ve got a place at the back and then another at the front where you connect one to another. Then it ends up in a big long line and those are, again, that pivot point that go around the flat plate.

Tara: And so, also, I think we want to pinpoint the bushing that goes here in the link weldment. How do you know how you replace these?

Colin: Yeah, so this is a really critical part. It’s one that doesn’t probably get enough attention out in the field. The bushing at the back is made out of bronze. It’s oil-impregnated, so that’s made to basically self-lubricate over time. But, as these wear out, if you do not replace this bushing, you replace this link weldment. It’s one or the other. You can either replace the bushing when it needs it, or you can wait, and what happens is you get an egg-shaped hole.

So, this steel is not as strong as the steel on a cam follower. So, as the steel on a cam follower is continuously pushing back and forth as it goes through the drive over years and years, you start to have wear into this piece of metal. This is a very thick bar piece of metal. It’ll stand up for a little while, but eventually you’ll start to get that egg-shape. You’ll create more slop throughout the carousel. You’ll start to get the crescent pallets will start opening and closing visually as they go throughout the carousel as the…it shifts from being pulled into the drive to being pushed out of the drive.

That basic pressure on this, over time, if you don’t do the right thing with your bushings and replace them, will start to compromise the integrity of the entire link weldments. And that becomes a pretty big refurbishment project.

Tara: Well, we hope we have answered some of your concerns and questions on link weldments. If you need help with these, we are definitely experts, so call us or email us and let us know how we can help you out. Thank you so much.