Powder Coating vs. Conventional Paint

Categories: Industry News | News | Technical Tips

Powder coating is a type of finish initially applied to metal components as a powder. The dry powder is either a thermoplastic or thermoset polymer.

The powder is applied electrostatically to a clean, grounded metal part by a gun, and then cured by heating the coated part to around 390°F in a large oven.  The heat causes the powder to flow and form a tough surface, as well as fuse to the metal. The result is a hard and durable finish tougher than conventional wet-applied paint finishes.

Other advantages powder coatings have include powder over-spray recovering and recycling, as well as the process emitting very little-to-no volatile organic compounds (VOC). Powder coating is an environmentally friendly process when compared to most conventional paints.

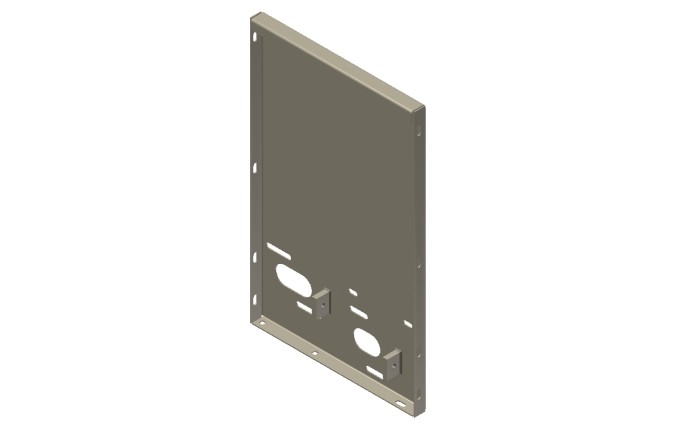

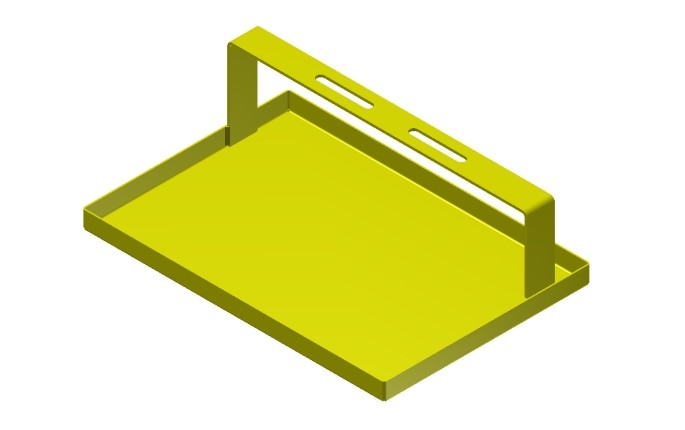

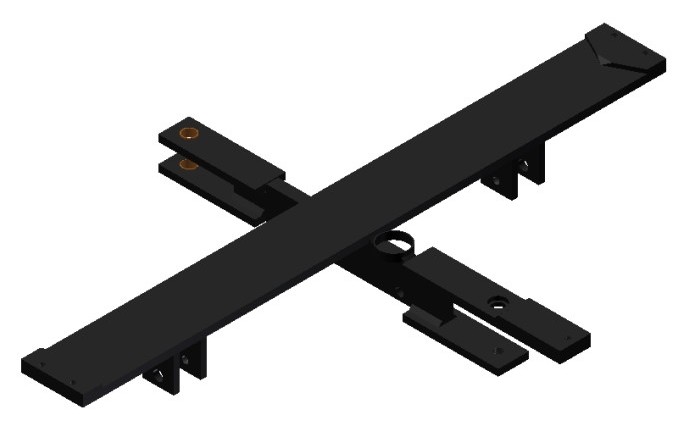

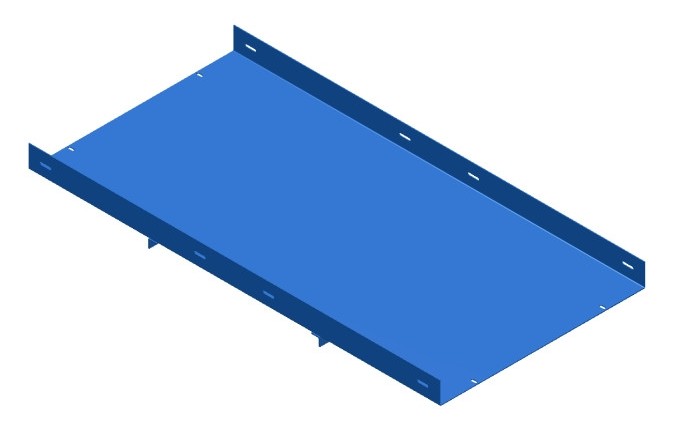

Unified Supply typically powder coats most metal baggage conveyor parts and components for the best end results. Airlines and airports may choose a specific color for their conveyor and carousel lines and most colors can be matched using the RAL color chart for either powder coat or wet-coat applications.